Leick Baumschulen is testing the first L25 Electric compact wheel loader from Volvo Construction Equipment, finding it to be a quiet, emission-free and easy-to-maintain addition to the tree farm and landscaping company’s fleet.

Based 30 minutes from the Volvo CE factory in Konz, Germany, where the L25 Electric will be produced from mid-2020, Leick Baumschulen is the first customer in the world to test this new ‘green’ machine.

The tree farm and landscaping company has been a Volvo customer for 34 years with a strong focus on sustainability and openness to new technologies related to environmental aspects. The highly-skilled operators at Leick Baumschulen use compact wheel loaders daily for a wide range of jobs – from pallet handling and loading material to grading and sweeping.

“This variety of tasks makes it the perfect real-world scenario for us to test our new electric compact wheel loader together with our customer,” says Paolo Mannesi, global compact wheel loader product manager for Volvo CE.

Having already invested in electric golf carts to comfortably show customers around its large yard and display area, Leick Baumschulen wanted to explore the advantages of electrification for its fleet of construction equipment too.

The owners of the company, Christoph and Michael Leick, strongly believe in electrification and see the benefits in line with their entrepreneurial thinking. They feel it is a big recognition from Volvo to be part of such development and are happy to know that they can contribute to future products with the experience they have in their segment.

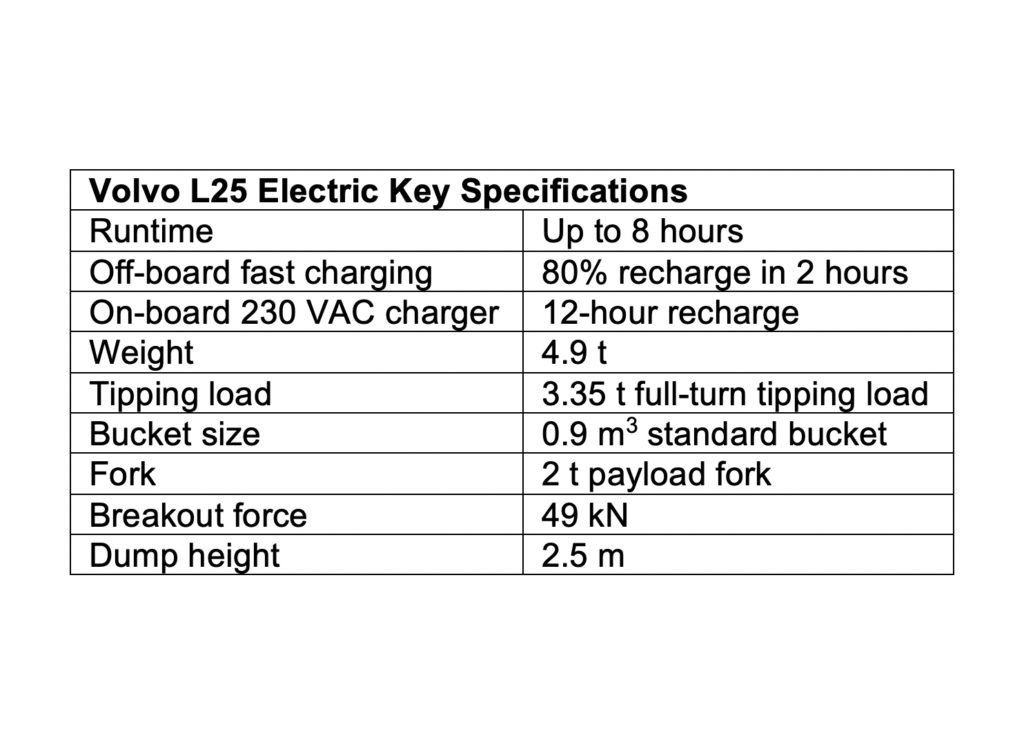

The Volvo L25 Electric is powered by lithium-ion batteries that cover an eight hour working shift with one single charge in the machine’s regular applications, which include light infrastructure work, gardening, landscaping and agriculture. The L25 also incorporates two dedicated electric motors – one for the drivetrain and one of the hydraulics. Decoupling the subsystems has led to higher efficiency across the entire machine.