Deconstruction and remediation specialist Liberty Industrial has gone from strength to strength since its establishment over a decade ago, with the privately owned Australian business having initially made a name for itself providing expert demolition consultation in the mining, energy and broader industrial sectors.

Founded in 2008, Liberty Industrial (Liberty) has over the years expanded its service suite to encompass specialist deconstruction, remediation, civil contracting, and industrial services, and has built a reputation as one of only a select few local demolition and remediation contractors capable of undertaking large and complex industrial projects.

With its headquarters in Sydney, Liberty employs more than 150 full-time staff and oversees offices in Perth, Brisbane and Adelaide, a workshop in Somersby, New South Wales. They have also recently established an office in the United Kingdom.

Liberty Director Simon Gill joined fellow engineer and Founding Director Clinton Dick at the company in 2010, with the two, who together draw on over 40 years of industry experience, having since presided over Liberty’s steady growth trajectory.

Simon told EEM that the business works in collaboration with a client base spanning the public and private sectors, and “generates value by providing complete solutions for large and complex demolition and remediation projects.”

“This is underpinned by our ability to offer a comprehensive range of integrated capabilities, including demolition, dismantling services, decommissioning and hazardous materials removal, industrial cleaning, land remediation, site rehabilitation, site preparation, and civil contracting and consulting services,” he explained.

“Continuity of works, an accelerated delivery schedule and cost savings are just some of the synergy benefits of our integrated services offering.”

EXPERTISE ACROSS COMPLEX DEMOLITION AND REMEDIATION PROJECTS

Liberty has put together a portfolio of work spanning some of Australia’s largest and most complex demolition and remediation projects, including the removal of refining facility and process plant infrastructure at Shell’s Clyde Oil Refinery, BHP Billiton’s Hot Briquette Iron Ore Plant and Rio Tinto’s HIsmelt Facility.

With Liberty drawing on a track record of innovation and overseeing a workforce which encompasses a broad range of skilled demolition and remediation professionals, Simon observed that “investment in the future is our priority.”

“We have set a new benchmark for the deconstruction, remediation and civil industries, cementing our status as a contractor of choice for the delivery of large and complex projects, near and far,” he told EEM.

“And for us, utilising the most advanced technology, plant, and equipment, in combination with our ability to leverage the best minds in the business, has ensured we deliver innovative, cost-effective solutions that maximise value for our clients and project stakeholders – every time.”

Industry recognition has subsequently come in the form of multiple World Demolition Awards, with Simon adding that Liberty is currently keeping busy across several major projects, including the Argyle Diamond Mine Closure project, being undertaken for Rio Tinto. In addition to this, Liberty is currently carrying out the Wallerawang Power Station Demolition for Greenspot, along with Chevron Australia’s, Thevenard Island Onshore Decommissioning and Remediation, and the Port Kembla Gas Terminal Early Works project for Australian Industrial Energy.

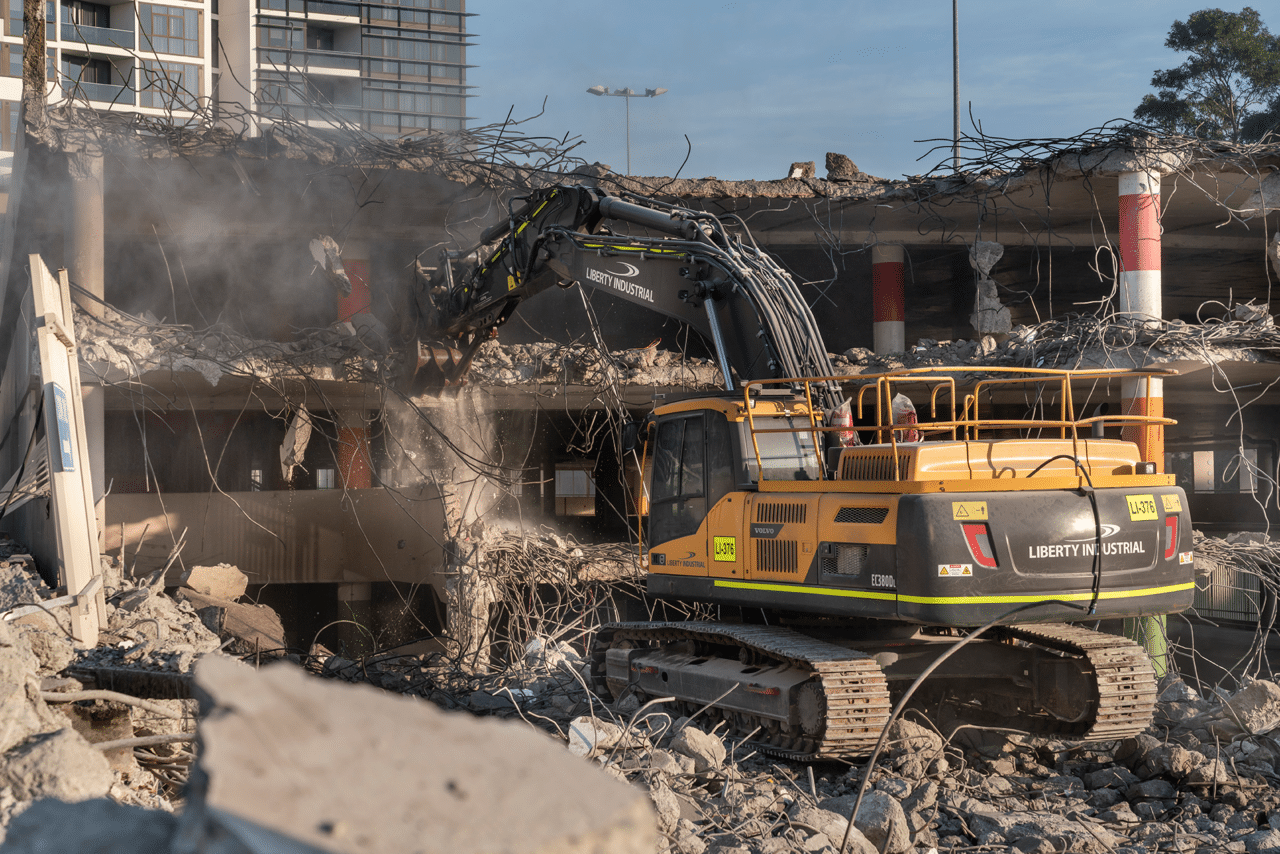

VOLVO EXCAVATOR FLEET GETS THE JOB DONE

When it comes to equipment, Simon said that Liberty has been working in conjunction with Australian construction equipment and truck distributor, CJD Equipment for over a decade, and during this time has steadily built its fleet of Volvo excavators.

“Our first major project was based in Western Australia, so we have always had a close relationship with Managing Director, Alan Barnett and the Perth team,” he said. “Our very first excavators were purchased through CJD in Perth – a Volvo EC330C, Volvo EC360C and two Volvo EC460Cs. “All of our excavators from the 95t and down are Volvo excavators, ranging from our EC750EHR and EC700, right down to the ECR88. The majority of our Volvo excavators are in the 360/380 and 250 classes.”

Steve Wilson, CJD Regional Sales Manager –who has been with CJD for 19 years, and who has worked with Liberty over the past decade – told EEM that Liberty has in this time added some 45 excavators to its fleet. “Volvo excavators suit Liberty for the ease of operation and the functionality of the hydraulics with their attachments,” he explained.

Among Liberty’s growing fleet are the Volvo EC250D, EC380D and EC480D excavators, with each model respectively sporting a range of features designed to deliver strong performance, productivity, and efficiency benefits.

The EC250D weighs in at an approximate operating weight of 25t, the EC380D 38t and the EC480D 49t, with the emphasis across these models firmly on increased power, greater digging force, and faster cycle times.

In addition to delivering a comfortable working environment for operators, including easy access to controls and superior visibility, a common feature across the range is fuel efficiency, underpinned by Volvo engine technology and functions such as ECO mode.

Meanwhile, durability is also a strong focus, encompassing robust machine components, from the boom and arm to the undercarriage, allowing the excavators to power on through in demanding conditions.

VOLVO EC750EHR: A PURPOSE-BUILT DEMOLITION MACHINE

Liberty has recently added the 95t (approximate operating weight) Volvo EC750EHR to its fleet, which Steve describes as “a purpose-built demolition machine, with a long arm providing greater reach and height for the demolition of multi-storey structures.”

Simon explained that Liberty had been looking for a machine capable of operating various sized shears at different pin heights. The company’s projects are typically steel structures with a focus on mechanical demolition.

“We had followed the development and release of the EC750EHR with great interest due to the varied boom configurations and attachment sizes possible,” he told EEM. “Due to the type of projects we undertake – including power stations, mine sites, oil refineries and heavy industrial structures – we needed to be able to mechanically demolish those structures with a range of shear sizes and varied working heights.”

Liberty is currently putting the EC750EHR to work on the Argyle Diamond Mine Closure project, tasking it with mechanically demolishing medium-rise heavy structures, utilising a 26m front with a 5t shear. “It is allowing us to safely and efficiently demolish steel structures previously out of reach,” Simon said. “It can change between its high-reach fronts and standard booms with ease, making it versatile and efficient to use across the entire project scope with a full range of attachments.”

He added that the feedback from operators “has been fantastic”, with the EC750EHR a stable and smooth machine to operate, even when at full stretch.

“The Volvo engineers have put a great deal of thought into making mobilising and demobilising smooth for those tasked with the job on site,” he said. “Hydraulic locking pins take the hard work out of assembling the boom sections, and a good line of sight between the operator and fitter ensures everyone involved can complete the job safely. “Transport and breakdown are made easier, with a retractable undercarriage and hydraulic counterweight remover enabling us to move the machine between projects more efficiently. Hydraulic couplers not only prevent oil spills, but also the risk of hydraulic injection. Robust cylinder and undercarriage protection make this a well-designed demolition machine.”

CJD CATERS TO EVOLVING MACHINE REQUIREMENTS

Steve told EEM that he has built strong ties with Liberty over the course of the past decade, assisting with the growth of its fleet, and taking care of the company’s varied and evolving machine requirements.

“I have dealt with Simon for 10 years, and more recently I have been dealing with the National Plant Manager, Kurt Denham, and we have a great working relationship, both professionally and personally,” he commented.

Simon observed that Steve has been on hand to assist and provide advice as required, as Liberty has grown and broadened its service suite, expanding to undertake a range of projects throughout Australia and abroad.

“We have a great relationship with Steve, he is very customer focused, loves the products, and is always keen to support us and our fleet of Volvo machines,” Kurt said.

“Steve is local to us in our Sydney head office but handles all of the plant purchases throughout Australia with CJD. This makes delivering machines through other CJD branches seamless and always to our exacting specifications.”

VOLVO EC750EHR SPECS

The heavy duty EC750EHR is designed to deliver power and versatility, with it running a Stage V 392kW Volvo D16J engine, and featuring:

- Working range and tool weight – a maximum pin height of 36m and pin reach of 22.273m, with a 10m reach below ground; a maximum tool weight of 3.6t (when working at maximum height); an operating angle of 24˚

- Multi-use – a second high-reach configuration has a 26m maximum pin height for use with a larger 5t tool, and a digging boom set with a 4.4m extension allows for an 18m pin height while using a tool up to 6.5t

- Stability – a hydraulically retractable undercarriage is specifically developed for the demolition segment (0.5m longer than the conventional EC750E); a track gauge of 4.3m

- Patented hydraulic modular joints – change from high reach to digging configuration using a two-pin hydraulic lock mechanism; a second hydraulic modular joint is on the extension boom, with a common interface between the extension boom and digging boom allowing for quick configuration

- Transportable – the retractable undercarriage features easy-to remove track frames, while the full counterweight can be hydraulically removed with an additional counterweight in one go

- Operator comfort – a comfortable and spacious cabin features a convenient layout of controls, with a large area of laminated glazing providing for good sight lines of the work area, while the cabin tilts to 30º, enhancing visibility and reducing operator strain and fatigue; includes a dust suppression system; a camera on the demolition arm delivers high-quality images to the in-cab display

- Added protection – the Volvo Care Cab includes a falling object guard and side impact protection, with the EC750EHR also sporting a heavy duty belly cover and under cover, a swing ring protection guard, and added protection on the boom and crusher cylinders.