A working partnership between SoilCyclers and CJD Equipment has evolved into an organic relationship that continues to grow.

Surface specialists SoilCyclers began as Brisbane Screening in 2009, servicing the soil, landfill mining and waste reduction services for the Brisbane area.

It’s now one of the market’s prime movers, working within the construction, waste and mining sectors across Queensland, New South Wales, Victoria, the ACT and Northern Territory.

The company recycles close to half a million cubic metres of soil annually, making it one of the largest soil recyclers in Queensland.

But it wasn’t always that way. It’s taken hard work for the business to take root.

Alison Price, SoilCyclers Managing Director says the financial capabilities of the business initially made growth difficult.

“When we first started, we were a new business, we didn’t have private funding so we started with what we could afford,” Alison says.

“As the company grew, reliability became an essential aspect of our business. We have incredibly expensive machines that work alongside excavators and skid steers and loaders.

“If they’re not working, everything is down, and nothing is making money. One machine breaking down is not just an independent issue, it can affect our whole operation.”

SoilCyclers provides a range of services for customers including topsoil amelioration, which turns soil from an unsuitable material to a specified topsoil ready for re-use on a project.

Soil remediation, waste reduction, mobile composting and soil testing is offered as part of a continually expanding service.

Reliable machinery is of paramount importance for SoilCyclers, with some projects requiring a range of equipment to be used.

“For us, reliability is really important, and it’s one of the reasons that we have been so happy with the Volvo machines that we use at our site,” says Alison.

Alison says she and SoilCyclers Plant Manager Michael Bennett underwent a thorough purchasing process to find the right equipment for their operation before purchasing a first Volvo machine in 2013.

“Michael and I drove around to all of the excavator dealers to look at their products for our operation. It got to the end of the day, and we drove past the CJD dealership,” Alison says. “As soon as I saw Michael look at the Volvo products, I knew they would be the machines we would buy.”

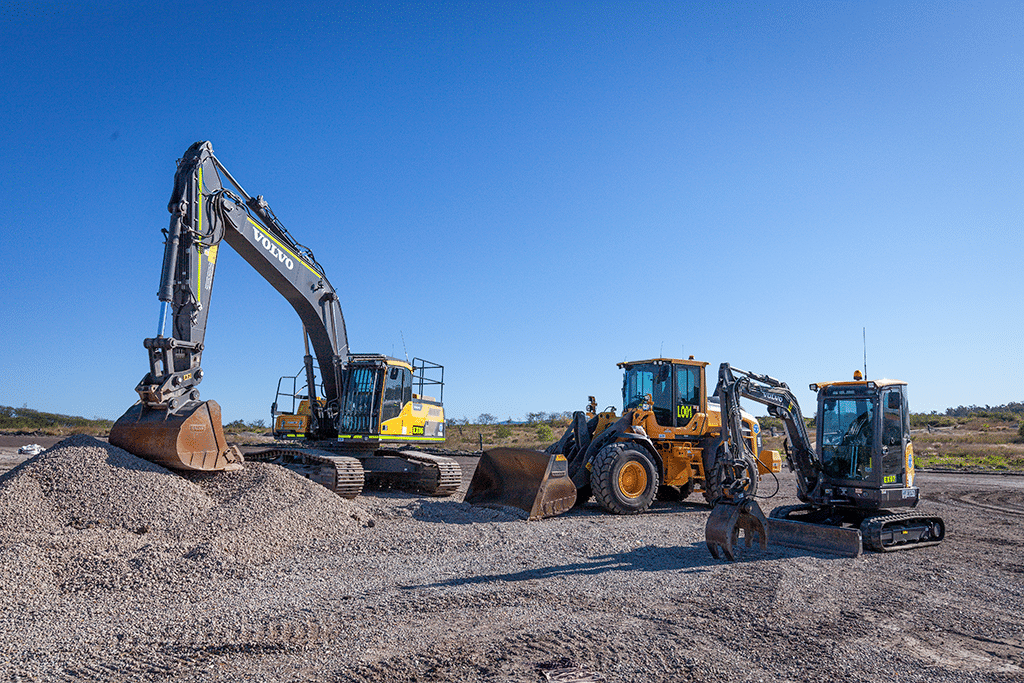

A range of Volvo products, including the L60H wheel loader, the ECR35D and the EC300D excavators, are now used by SoilCyclers for digging in waste stockpile and material movement.

The Volvo ECR35D comes with a quick coupler design, allowing operators to change attachments quickly, thanks to mechanical and hydraulic universal couplers.

Its range of attachments also allows the machine to be productive in a range of applications, with different buckets, hydraulic breakers, hydraulic thumbs, and tilt rotators able to be attached.

Michael says Volvo machines offer a balance of ease-of-operation and versatility.

“We really like the general layout of the vehicles, which includes the engine bay, and the user-friendliness of the design.”

He says the power and efficiency of the L60H wheel loader is a far cry from the outdated machinery the company previously used.

“When we are completing remediation jobs with materials such as organics, the wheel loader allows us to move the material closer for the excavator, so that it can be mixed through the screening plant,” Michael says.

“We used to have skid-steers, but it got to the point where we needed something a bit bigger. Within the first month of using the wheel loader we discovered that it was using about half the fuel that the skid steer was using, while it was doing ten times the work.”

“We were really thrilled with that, and we now have three of those vehicles in our fleet.”

The L60H also features the latest ‘Stage V’ engine emission technology, providing reductions in fuel consumption, and increased load productivity.

Increased safety features including anti-slip steps, improved cooling capacity and greater maintenance access points for both the Volvo excavator and wheel loader were added incentives for SoilCyclers when looking for the right equipment.

“One of the buying criteria that we had when we were first looking at an excavator in 2013 was a machine that had electric hydraulic controls. Volvo was one of the companies that made early movement towards that feature,” Alison says.

Durability is also a key factor for SoilCyclers. It’s Volvo machines which far exceed expected maintenance intervals, she says.

“Some of our Volvo vehicles are starting to accumulate some serious operation hours,” Alison says.

“We normally aim to change over excavators approximately every 6000 hours. We estimate that our vehicles won’t require any significant maintenance until 10,000 hours of operation.”

Stacey Brown, Regional Sales Manager of CJD, says that a constant support service is available for customers such as SoilCyclers.

“CJD Equipment has branches in all states and territories delivering parts, service and repairs 24/7 for all Volvo CE, ensuring our customers have reliable, productive machines delivering a lower cost of ownership to their business,” he says.

CJD Equipment field service technicians have carried out general maintenance on-site for SoilCyclers’ Volvo machines.

SoilCyclers is aiming at further growth and larger projects which, Alison says, will likely require more machinery.

“We brought in our first Volvo machine in 2013, so our relationship with the company has been quite a long one. For future equipment, I won’t bother shopping anywhere else,” Alison says.

Stacey Brown of CJD adds that the Volvo machinery go beyond just satisfying manufacturing and service requirements.

“Volvo CE is built on the cornerstones of safety for operator and sites, quality of components and care for the environment throughout the manufacturing process, as well as machine recycling at end of life,” Stacey says.