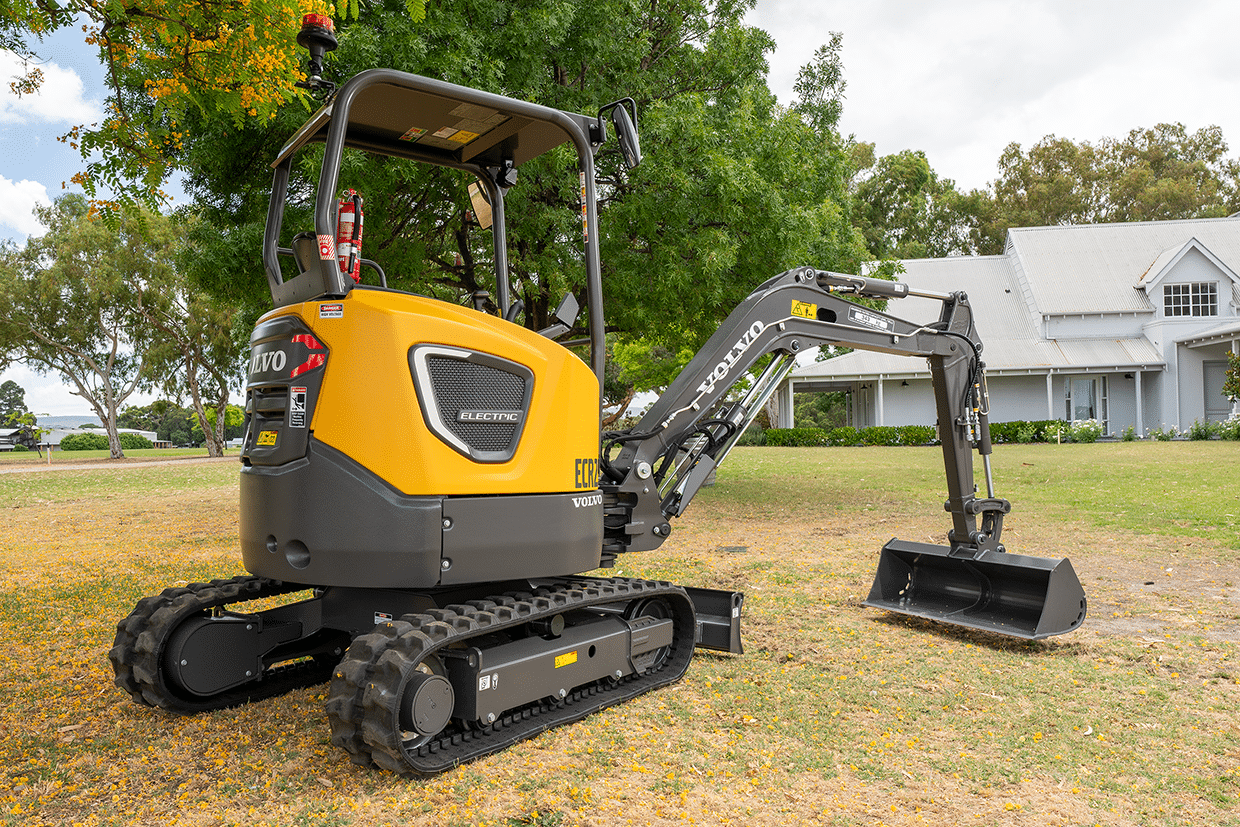

CJD Equipment proudly introduces a lineup of compact electric machines to Australia. Among them are the Volvo ECR18 and ECR25 Electric compact excavators, and the L25 Electric wheel loader. If you’re contemplating embracing a more environmentally conscious path forward, here are five reasons why you should consider Volvo electric construction equipment for your business.

Reason 1 – Say goodbye to loud diesel machines and hello to quieter worksites.

Electric machines boast significantly lower noise levels compared to their diesel counterparts. This advantage is particularly beneficial in noise-sensitive environments where diesel machines may be restricted.

Diesel engines rely on the combustion of fuel to generate power, which essentially creates noise due to the movements within the engine. As electric machines do not have combustion engines, thereby eliminating the presence of loud noise associated with fuel combustion.

Electric motors deliver power more consistently and instantly compared to diesel engines, which often need to rev up and down. This means electric machines can operate at more consistent RPMs, which contributes to a more stable and quieter operation.

Reason 2 – Create a Safer Environment that is Sensitive to Emissions.

The absence of exhaust emissions from Volvo electric construction machines not only helps to improve local air quality but also reduces the overall carbon footprint associated with construction activities.

By operating with zero emissions, Volvo electric construction machines have the advantage of accessing environments such as indoors or underground, densely populated areas, or locations where emissions could pose significant health or environmental concerns. This capability enhances the work experience for operators and opens up new business opportunities. By allowing construction in areas where traditional diesel-powered equipment may be restricted, these machines allow companies to work on zero-emission job sites without compromising productivity.

Electric construction machines also assist companies in meeting strict environmental regulations, showcasing their dedication to sustainability and responsible business practices, creating a safer, cleaner, and more sustainable construction sector, benefiting both businesses and communities.

Reason 3 – Align your Sustainability Targets by Choosing Electric Equipment.

Many businesses aim to meet sustainability goals in line with initiatives like the science-based target initiative and the Paris Agreement.

Setting science-based goals shows a company’s commitment to sustainability and environmental care. Not only does this practice enhance brand reputation, but it also creates trust and appeals to socially conscious consumers.

Environmental aspects are becoming increasingly important in investment decisions. Companies investing in zero-emission construction equipment can reduce their carbon footprint and is a step forward for a cleaner and greener future.

By embracing electric solutions pioneered by Volvo CE, businesses can achieve environmental benefits without compromising performance. This not only aligns with sustainability objectives but also positions them as leaders in the transition towards a more eco-conscious industry.

Reason 4 – Create a Healthier Work Environment and Improve the Safety for your Operators.

These machines produce minimal noise, less vibrations, and zero emissions promoting better environmental conditions. The electric motors are significantly quieter than their diesel equivalent and have fewer moving parts resulting in a reduction of vibration and noise.

This creates a conducive environment where operators can effectively communicate with coworkers, easily hear warning signals, and maintain situational awareness while working.

Overall, this will enhance the operator’s comfort, especially during extended operations periods contributing to a safer and healthier work environment.

Volvo’s dedication to advancing safety standards, prioritising operator safety and comfort, businesses can improve risks and create a workplace that prioritises well-being and productivity.

Reason 5 – Reduced your Downtime and Operational Costs for your Business.

The battery system of electric machines eliminates the need for maintenance, resulting in decreased downtime and lower operating expenses. Additionally, electric machines are generally cheaper to run with energy compared to their diesel counterparts, contributing to decreased operational costs.

With fewer components requiring regular maintenance, electric machines typically have longer service intervals, allowing businesses to optimise their operations and minimise disruptions.

By eliminating oil changes, fuel filter replacements, or other maintenance associated with diesel engines, it translates to reduced downtime for servicing and decreased labor costs throughout the lifespan of the equipment.

If you would like to find out more, please reach out to your local CJD branch or phone 1300 139 804.