Volvo Construction Equipment (Volvo CE) stands at the vanguard of the construction sustainability movement, demonstrating a robust commitment to transforming the industry by driving impactful change through every part of the value chain [1]. With an eye on the future, Volvo CE underscores its dedication to sustainability by setting ambitious targets, including achieving net-zero greenhouse gas emissions by 2040 and introducing zero-emission construction equipment into Australia—attesting significant strides towards more sustainable construction practices [3].

A holistic sustainability approach is central to Volvo CE’s philosophy, balancing economic development with environmental stewardship and social responsibility. This article presents how Volvo CE’s innovative technologies and keen focus on fuel efficiency and carbon footprint reductions furnish the construction industry with a path to attain net-zero emissions and why they are considered a leading choice for sustainable procurement within the heavy construction equipment sector [1] [2] [3].

What is sustainable procurement?

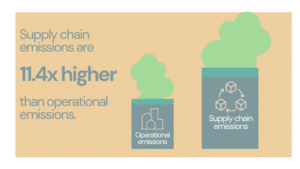

Sustainable procurement within the construction sector is paramount to driving forward an industry synonymous with significant environmental impacts. Companies can foster a more sustainable construction approach by integrating environmental considerations into procurement decisions. Volvo Group’s commitment to this initiative is evident through its rigorous supplier expectations and the promotion of sustainability across the entire value chain [4] and [5].

- Sustainability Requirements: A study highlights 17 essential requirements for construction procurement processes. These include:

- Compliance with environmental laws [5].

- Evaluation of the environmental friendliness of products [5].

- Consideration of optimal energy and water consumption [5].

- Supply Chain Management: The Volvo Group insists on eliminating harmful substances from products, mandating suppliers adhere to Volvo standards regarding substances of concern. This approach ensures the quality of materials and services and promotes ethical and sustainable supply chain practices [4].

- Strategic Sourcing: Sustainable procurement in construction is not solely about sourcing materials; it’s about embedding sustainability into procurement policies and processes. This strategic approach aims to reduce negative environmental impacts [6], promote social responsibility [6], ensure economic viability [6], minimise the industry’s carbon footprint [10], and encourage the use of lower-impact products and materials [10].

Adopting sustainable procurement practices is crucial for the construction industry to maintain resilience to changing market dynamics, resource availability, and consumer preferences. By focusing on strategic sourcing and integrating sustainability considerations, the construction industry can significantly reduce its environmental impact and contribute to sustainable development goals [7][8][9][10].

The Environmental Benefits of Choosing Volvo CE

Volvo Construction Equipment (Volvo CE) has taken significant steps to ensure its operations and products contribute positively to environmental sustainability. The company’s commitment to reducing its carbon footprint is evident in several key areas:

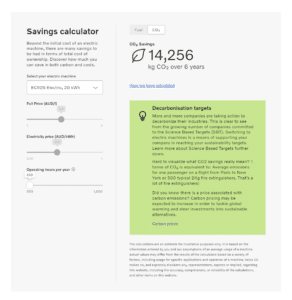

- Carbon Footprint Reduction: Aiming for net-zero greenhouse gas emissions by 2040 aligns with the Paris Climate Agreement’s ambitions [1]. The introduction of zero-emission construction equipment in Australia supports the transition to a low-carbon economy [14]. Volvo CE’s operational emissions have been cut by half at their Changwon facility, thanks to the installation of photovoltaic solar panels [2].

- Circular Economy and Recycling Initiatives: Industry-leading recycled parts through CE Parts can save up to 80% in carbon emissions compared to new part production [2]. Volvo Reman offers refurbished parts that reuse 85% of original materials, drastically reducing CO2 emissions and requiring 80% less energy than manufacturing new components [11]. Adopting Volvo-approved used equipment can save approximately 100 metric tonnes of CO2 emissions, demonstrating a commitment to the circular economy [11].

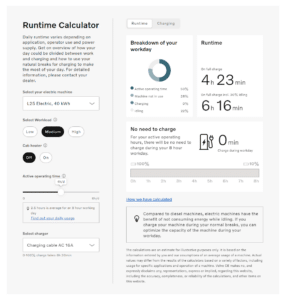

- Electrification and Innovation: Volvo CE is electrifying its vehicle offerings, including mining equipment, to decrease carbon emissions significantly [13]. Electric construction equipment, such as the ECR18 and ECR25 electric excavators and wheel loaders, provides lower operating costs, reduced emissions, and the potential for longer work hours [12] [13]. The company’s hybrid excavators, like the EC300E, offer up to 15% lower fuel consumption and reduced emissions [16].

By integrating these sustainable practices, Volvo CE is reducing the environmental impact of its products and leading the construction industry towards a more sustainable future. Their efforts are a testament to the potential for heavy construction equipment to be both high-performing and environmentally conscious.

Economic Advantages for Australian Businesses

Volvo Construction Equipment (Volvo CE) leads sustainable practices and offers economic advantages that can significantly benefit businesses. These advantages stem from a comprehensive approach that underscores resource conservation, cost efficiency, and machine reliability.

-

- Circular Economy and Cost Savings: Volvo CE conserves resources by adopting a circular economy approach, which translates into direct cost savings for businesses [11]. The Volvo Certified Rebuild programme extends the life of construction machines, allowing businesses to save on capital expenditure by refurbishing equipment with Volvo-approved used parts that meet the latest technical specifications [11].

- Resale Value: Maintaining machines well, performing regular repairs, and minimising damage can increase the resale value of used equipment, providing a better return on investment when the equipment is sold [12].

- Operational Efficiency and Predictive Maintenance: Cooperative purchasing agreements offer the potential for cost savings and streamlined procurement processes, making it easier and more cost-effective for businesses to acquire the needed equipment [12]. Volvo CE’s midsize excavators are designed for adaptability, allowing businesses to transition efficiently between projects of varying sizes, leading to increased productivity and efficiency [12]. Implementing Volvo fluid analysis with AI technology can preemptively identify part failures and machine misuse, significantly reducing downtime and lowering the total cost of ownership [12].

These strategies, combined with Volvo CE’s commitment to sustainable construction and its targets for electric sales and net-zero value chain emissions, position the company as a partner for businesses looking to enhance their economic viability while contributing to a sustainable future [16] [19]. Volvo CE’s partnership with CJD Equipment and collaborations with companies like CRH, also targeting significant emissions reductions, reflect a shared vision for a sustainable and economically prosperous construction industry [19].

Innovations and Technologies in Sustainable Equipment

Volvo Construction Equipment (Volvo CE) is at the forefront of innovating sustainable solutions within the construction industry. Their commitment to sustainability is driven by focusing on three main areas: people, climate, and resources, ensuring a holistic approach to industry transformation [1].

- Collaborative Innovation: Engaging with PhD students and specialists, Volvo CE fosters a dynamic exchange of ideas, energizing the process of industry transformation [2]. This collaboration also highlights the importance of gender balance in product development, recognizing the role of diversity in driving sustainable business practices [2].

- Cutting-Edge Concepts: The Concept Lab is a hub for innovation, showcasing future-focused ideas like AI-enabled automation and fuel cell prototypes designed to meet emerging customer needs and expedite industry transformation [17]. Volvo CE’s innovations span a wide range, including electrification and hybrid technology, autonomous and connected solutions, active safety systems, eco-friendly designs, advanced control systems, and material efficiency, all contributing to a more sustainable construction industry [18].

-

- Technological Advancements:

- Electric Machines: The ECR25 Electric Compact Excavator, introduced in Australia, provides a zero-emission solution with a powerful 22.3 kN breakout force and a 20-kWh battery array capable of 3–4 hours of operation per charge, with optional fast charging available [18].

- Productivity Services: Volvo CE’s productivity services, including Connected Map and Task Manager and innovative offerings like Equipment as a Service and the CO2 Reduction Programme, emphasise efficiency and sustainable operations [18].

- Connected Solutions: Real-time insights into work performance are made possible through Volvo Co-Pilot and Volvo Assist software, which help identify inefficiencies proactively, ensuring operations are as sustainable as they are efficient [16].

Volvo CE’s dedication to sustainability is evident through its continuous investment in technologies that not only meet current demands but also pave the way for the construction industry’s future. Its strategic approach to innovation ensures that sustainability is woven into the fabric of its operations and product offerings.

Conclusion – Why Volvo Construction Equipment is your Best Bet for Sustainable Procurement of Construction Equipment.

Volvo Construction Equipment is a compelling choice as an upstream construction equipment supplier for ESG or sustainable reasons due to its strong commitment to sustainability and innovative initiatives. Volvo CE is dedicated to developing a cleaner, more intelligent, and more connected world through imagination, hard work, and technological innovation. [21]

Volvo CE has also made significant strides in sustainability by delivering the first construction machine made with fossil-free steel, showcasing its commitment to decarbonising the construction industry. [23]

Moreover, Volvo Group collaborates with CRH to accelerate decarbonisation in the construction industry by focusing on net-zero innovations for on-road vehicles and off-road equipment. [24]

This partnership aims to reduce emissions significantly, with Volvo Group targeting 35% fully electric sales by 2030 and CRH aiming for a 30% reduction in group-wide emissions by 2030. [24]

By joining forces, both companies are driving towards a more sustainable future in construction. Volvo Group’s sustainability reports reflect its dedication to reducing emissions and achieving net-zero value chain emissions by 2040. [25]

The company’s ambitious targets within the Science-Based Targets initiative demonstrate its commitment to pushing boundaries and leading towards a more sustainable future. With a focus on electrification and transitioning towards decarbonisation, Volvo Group is actively working towards a greener tomorrow through innovative solutions and partnerships [25]

FAQ’s

What are the fundamental elements of Volvo’s sustainability strategy?

Volvo’s sustainability strategy is founded on three essential elements: economic responsibility, which focuses on financial ethics and profitability; social responsibility, which emphasises the well-being of employees and communities; and environmental responsibility, which is dedicated to minimising the environmental footprint and promoting ecological health.

What is the Science-Based Target Initiative (SBTi)?

The Science-Based Targets Initiative (SBTi) collaborates with reputable organisations such as the United Nations, the World Wide Fund for Nature (WWF), and the World Resources Institute. It provides a globally acknowledged framework for climate action, assisting businesses in determining how much and how rapidly they need to reduce their emissions to avoid the worst effects of climate change.

The SBTi framework ensures that targets are assessed and validated by a team of experts per the most recent scientific findings and the goals of the Paris Agreement. Setting science-based targets allows businesses to take tangible steps to cut carbon emissions and contribute to a more sustainable future.

Why is it essential for Australian construction and mining companies to establish science-based targets?

Setting science-based goals is critical for Australian businesses for various reasons.

Addressing climate change is critical for reducing the risks associated with catastrophic weather occurrences, resource constraints, and regulatory changes. Australian businesses should proactively address these risks by establishing science-based goals and ensuring long-term resilience.

Enhance Brand Reputation: Setting science-based goals shows a company’s commitment to sustainability and environmental care. It improves brand reputation, builds trust, and attracts socially conscious customers.

Drive Innovation: Setting ambitious emissions reduction targets encourages innovation within a corporation. It promotes the development of new technologies, processes, and products that help to achieve a low-carbon economy.

Attract Investors: Environmental aspects are becoming increasingly important in investment decisions. Companies that pursue science-based goals are more likely to receive investment and financing from sustainability-focused investors.

Sector-specific guidance

The SBTi offers sector-specific information to assist firms in various industries in setting science-based targets relevant to their operations. This guidance considers the unique problems and opportunities that each sector faces in assisting businesses in navigating the intricacies of emissions reduction within their industries.

The SBTi’s guidance covers several industries, including:

-

Aluminium

-

Aviation Buildings

-

Chemicals used in cement production

-

Forestry, Land, and Agriculture (FLAG)

-

Information and communication technologies (ICT)

-

Maritime Oil and Gas Power Steel

-

By providing specialised guidance, the SBTi guarantees that firms in all sectors may build effective strategies to cut carbon emissions and contribute to a more sustainable future.

Some of the primary resources available are:

-

Commitment handbook: a detailed handbook outlining the methods and conditions for committing to science-based objectives.

-

Target Validation Criteria: Specific criteria for developing a science-based target and the validation procedure.

-

Target Setting Tool: This tool assists firms in developing emission reduction objectives based on the SBTi’s criteria.

-

Case Studies: These are real-world examples of businesses that effectively set and met science-based goals, demonstrating best practices and lessons learned.

-

Measurement, Reporting, and Verification (MRV) Guidelines enable firms to measure, report, and verify their emissions reductions reliably.

-

Net-Zero Guidance: Resources and guidance for businesses seeking to match their objectives with net-zero emissions ambitions.

These resources offer essential insights and practical tools businesses may use to manage the complexity of setting and meeting science-based targets.